Pridgeon & Clay takes a holistic approach to product development, working to be an essential partner with our customers throughout the product life cycle. Our experience and engineering, testing, and production resources allow us take products from the early development stages through to serial production.

This collaborative approach provides our customers with shortened lead times, robust processes, and increased quality. We provide engineering, design, testing, and manufacturing support for stampings, precision machined parts, and assemblies, taking concepts from bench science to production. We specialize in developing the robust processes that move production from runs of dozens to millions.

Our experienced staff, combined with our constant investment in leading in leading-edge technology, brings products to market for the automotive, trucking, medical and consumer products industries. Let Pridgeon & Clay be your product development partner. Contact us and we’ll discuss how we can help.

As your partner in the product development process, Pridgeon & Clay has the engineering expertise to take a product from concept through to production. As consumers and government regulations speed the rate of change in the market, we are your partner in bringing innovation in design, process and technology to consumers.

Let us help you make your products cleaner, safer and lighter. Our engineering services will help you every step of the way, bringing concepts from the initial bench science through development, launch and production.

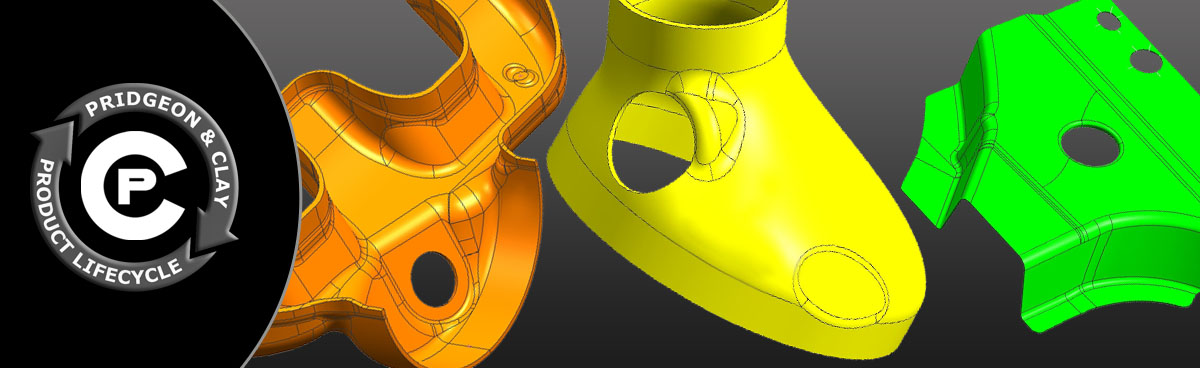

Our complete suite of design software CFD, and FEA allows us to develop robust production processes that ensure that there are no surprises when the product is launched. From our simulations, we can recommend design changes to reduce costs and improve functionality.

Product Lifecycle: Prototype

Product Lifecycle: Product Validation & Manufacturing Analysis

Product Lifecycle: Launch

Product Lifecycle: Tool Build

Product Lifecycle: Production

With a fleet of more than 100 presses worldwide, we are able to support global platforms for our customers across North America and Europe. We are focused on Continuous Improvement, and are constantly looking at ways to improve our processes. Lean manufacturing is central to Pridgeon & Clay’s culture – we look to drive waste from our systems.

Pridgeon & Clay's Lean System uses a variety of approaches to achieve sustainable improvement throughout our production and business processes. Our goal be highly responsive to customer demand while producing top quality products in the most efficient and economical manner possible. We achieve this by creating an environment of teamwork that encourages customer focus, team recognition and continuous improvement in all areas of operations.

Pridgeon & Clay has adopted several lean tools that collectively make up the Pridgeon & Clay House of Lean. These tools include 5S, Standardized Work, Kanban, Quick Set-up, Error Proofing, Continuous Improvement Activities, Problem Solving, and Six Sigma.

Copyright © 2014 - All Rights Reserved - Pridgeon & Clay